Posted on March 4, 2024 by Storm Goodman

The uTurbine is their project and is a turbine design that has the potential to reinvent the way the public sees wind energy.

The Makerspace is a place where students of all Klesse College majors can utilize to explore their wildest dreams and ambitions, and for the Windrunners and GustBusters, the Makerspace is a place where they can realize, design, and build their vision for a better future of wind energy. The uTurbine is their project and is a turbine design that has the potential to reinvent the way the public sees wind energy. Unlike the standard horizontal-axis wind turbines that we are accustomed to seeing, the uTurbine is a vertical-axis turbine, which is a wind turbine design that remains largely unexplored.

The uTurbine group, made up of some of the brightest minds across three different majors at Klesse College, came together on this project to develop their vertical-turbine design that could remedy some of the issues of traditional horizontal-axis turbines to help humanity bolster its energy production while still keeping greenhouse gas emissions low.

Horizontal-axis turbines are large machines that require lots of space to operate, space that must be dedicated solely to the turbine. These turbines are only able to collect wind in one direction, meaning that their placement has to be precise and in large clearings to capture the wind. Because of their size and land requirements, everywhere that could house and properly support a horizontal-axis wind turbine already does. To combat our ever-growing energy needs, scientists are looking towards the installation of turbines offshore. The challenge with this is that the stand horizontal-axis turbines are too top-heavy and require a massive and expensive foundation to prevent them from falling over amidst ever-changing wind and water conditions. This was a challenge the WindRunners and GustBusters were happy to accept.

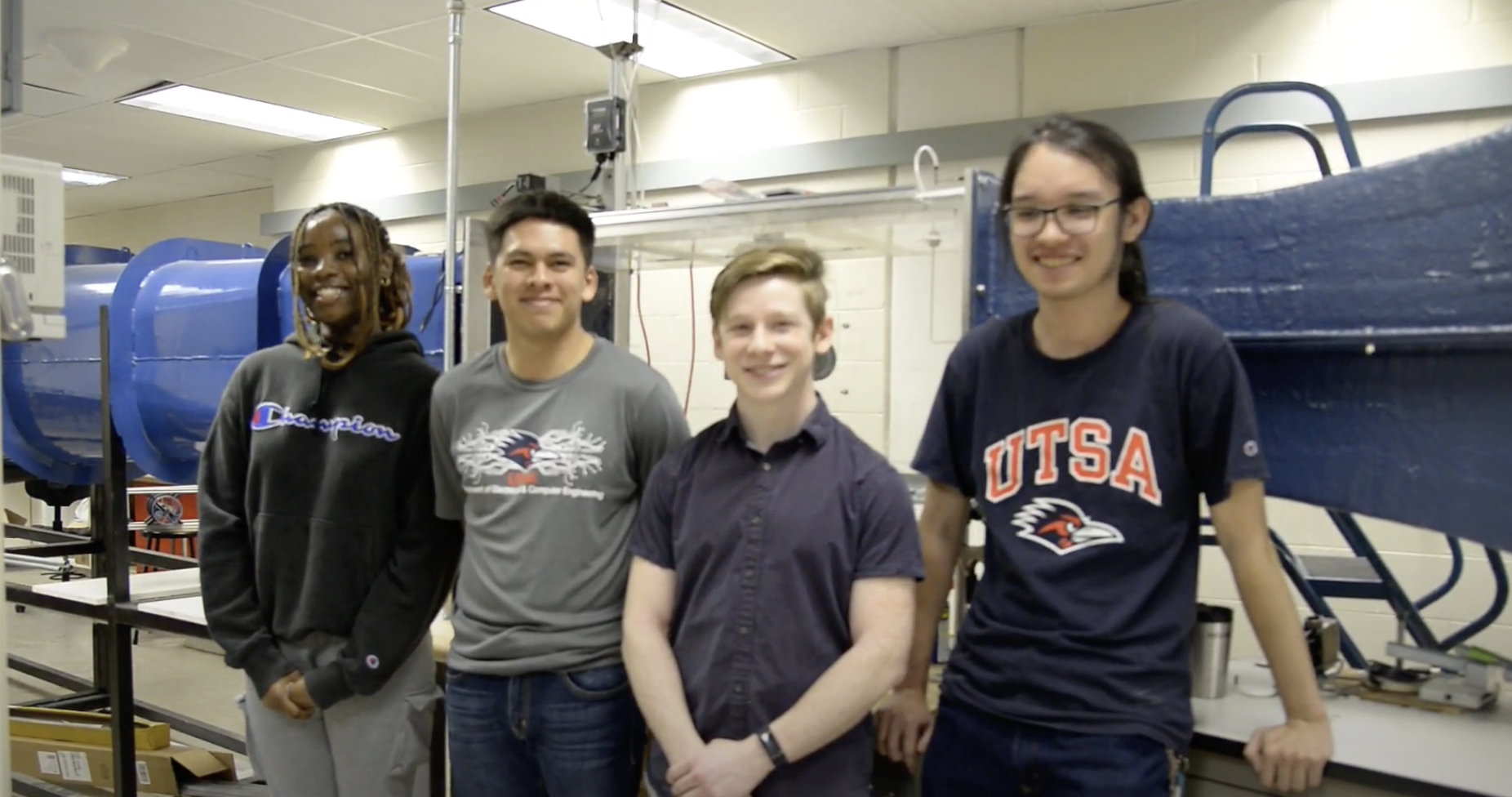

The WindRunners, a team of four mechanical engineering students, are in charge of the designing and construction of the physical turbine element. Throughout development, the WindRunners utilized the Griffin Lab wind tunnel to test and explore how their designs would hold up against various levels of wind speed. Roger Gardner served as the team’s engineering analyst, Reillan Sawyer was the team's design engineer, Christian Garcia was the team’s CAD designer, and Justin Palacios was the team’s test engineer.

The GustBusters, a team of six students consisting of both computer and electrical engineering students, are in charge of developing a system that could accurately self-regulate itself based on the wind conditions. A vertical-axis turbine can receive wind on all of its sides, so it runs the risk of having the parts wear down faster. To solve this issue, the GustBusters developed an internal system that could measure the current wind conditions and regulate the spinning of the turbine to prevent this weardown. Osenimu Ayeni and Christian Balditt were the two computer engineers on the GustBusters and were in charge of hardware engineering and software engineering respectively. Abram Garcia, Jesus Guillen, Micheal Sztary, and Victor Flores are all electrical engineers working on the different aspects of software and hardware engineering.

The uTurbine would require much less space than traditional turbines and would have its weight distributed rather evenly throughout, letting it function offshore on a less costly support platform. Due to its smaller size and ability to collect wind omnidirectionally, the uTurbine can also be placed in urban areas to generate energy.

Going forward, the next step for the uTurbine group is to integrate the turbine element created by the WindRunners and the computer components engineered by the GustBusters, but based on how much progress this team has made already and their seamless cooperation throughout every step of the way, there is no doubt that this next step will be a breeze.

This story is a part of the Makerspace Mondays series.